Atos develops digital solution to calculate product carbon footprints within the chemical industry in partnership with BASF

Atos and BASF have launched a digital solution for companies in the chemical and process industries to identify, monitor, and eventually reduce the carbon footprint of chemical products. For this purpose, BASF provides its digital solution and methodology for calculating the Product Carbon Footprint (PCF) of chemical products and selected Atos as a partner for the development of a software platform based on this methodology to make the PCF calculation approach available to the industry.

The PCF platform addresses multiple challenges for chemicals product carbon footprints

Many chemical processes create multiple outputs. Within LCA this requires allocation1

The PCF platform provides a recognized allocation hierarchy consistent across the portfolio

Chemicals companies often produce themselves products that are then used for other products

The platform enables calculation of PCFs for products with an “internal supply chain” consistently and transparently

Many Product Carbon Footprints use generic or estimated data for emissions from energy

Assessing the entire product portfolio, the PCF platform directly links a company’s corporate carbon footprint (Scope 1&2) with PCFs

Most PCFs rely on secondary data (e.g. LCA databases) for raw material emissions

The PCF platform is set up to both provide and allow for use of supplier specific PCF data. This provides higher accuracy and ability to reduce emissions

1 Allocation is partitioning emissions from a multi-output process to individual outputs

Product Carbon Footprint: PCFs summarize the specific amount of greenhouse gas (GHG) emissions that are associated with a product throughout its life cycle

The methodology from BASF is certified by TÜV Rheinland and complies with ISO requirements and the Greenhouse Gas Protocol Product Standard as well. Through it, you can assess your portfolio and production network in terms of CO2 emissions and take action to reduce your PCF. In addition, the approach can support you to adjust to future climate legislation.

√ ISO compliant

√ TÜV certified

The PCF platform calculation schematic

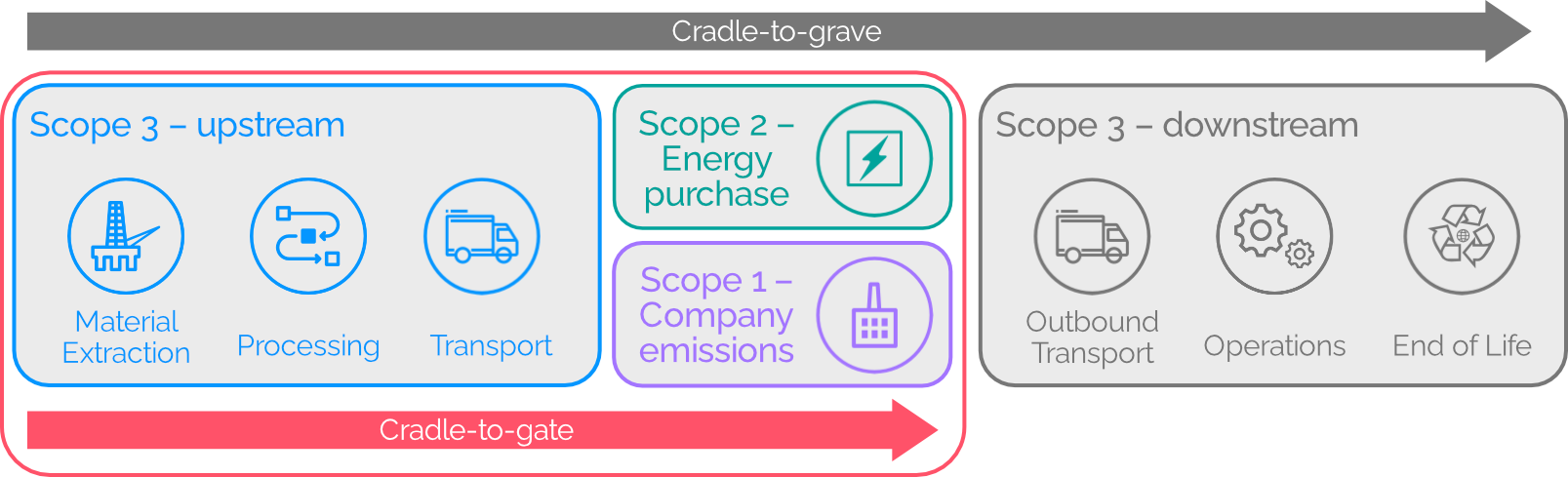

The PCF calculation schematic produces results in a declared unit of “1 kg of product unpacked, at factory gate”. Additional phases such as packaging, downstream transport, and end of life can be added subsequently as required by the customer, such extending the solution to a full cradle-to-grave scope.

The calculation will cover 98% of material and energy inputs at a minimum. A key feature of the PCF methodology is its ability to capture the emissions associated with internally produced raw materials. A key benefit of this methodology is that it relies on data that’s typically available within existing IT systems. This enables automatic calculation of a large number of product carbon footprints.

Carbon Minds environmental life sciences data to complete Atos Carbon Footprint Platform (PCF)

“Carbon Minds provide data on the environmental impacts of chemicals and plastics. Our data fits perfectly with the Product Carbon Footprint Platform from Atos. Together we enable more accurate assessments of supply chain emissions, environmental target setting, and decision making for carbon footprint reduction.”

Arne Kätelhön, CEO & Co-founder, Carbon Minds.

Since its launch, Atos Scaler has fostered open innovation projects that are ever closer to customers’ business needs. At Scaler, decarbonization is one of our main objectives, the accelerator program is now made up of 50% of start-ups that offer sustainable transformation solutions. Atos Scaler has a strong portfolio of decarbonization services that allows to be the leaders in secure and decarbonized digital.

Carbon Minds’ solution will be integrated into the PCF platform based on BASF IP protected calculation methodology. By that, the platform will be enriched with a large amount of highly regionalized and supplier-specific chemical data.

Customers will have access to a bigger market. The goal of this PCF Platform is to make it an industry standard for Product Carbon Footprint calculation processes in the chemical & process industry. Carbon Minds solution being part of the PCF Platform will grow its market share.

Contact us

Our Experts

Nils Pohlmann

Business Developer

![]()

Ann-Kathrin Lieck

Sustainability Consultant

![]()

Michelle Dürksen

Sustainability Consultant

![]()